Protective Coating of Electronics – Defect Root Causes, Failure Mechanisms and Quality Evaluation Tools

Dr. Markus Meier, Dr. Helmut Schweigart

» free «

Brief Insight

Conformal coatings protect electronic assemblies under demanding climatic conditions—provided they remain free of cracks, delamination, and blistering. The whitepaper explains how moisture-induced failure mechanisms develop, why low- and high-voltage devices respond differently, and how coating reliability tests quickly reveal coating quality and moisture sensitivity. A concise overview of the most important test procedures.

Originally published in the proceedings of the Electronics in Harsh Environments Conference, Amsterdam, Netherlands, 23-25, May 2023.

Delivery form: PDF

Article number: EN-2511-11

White paper

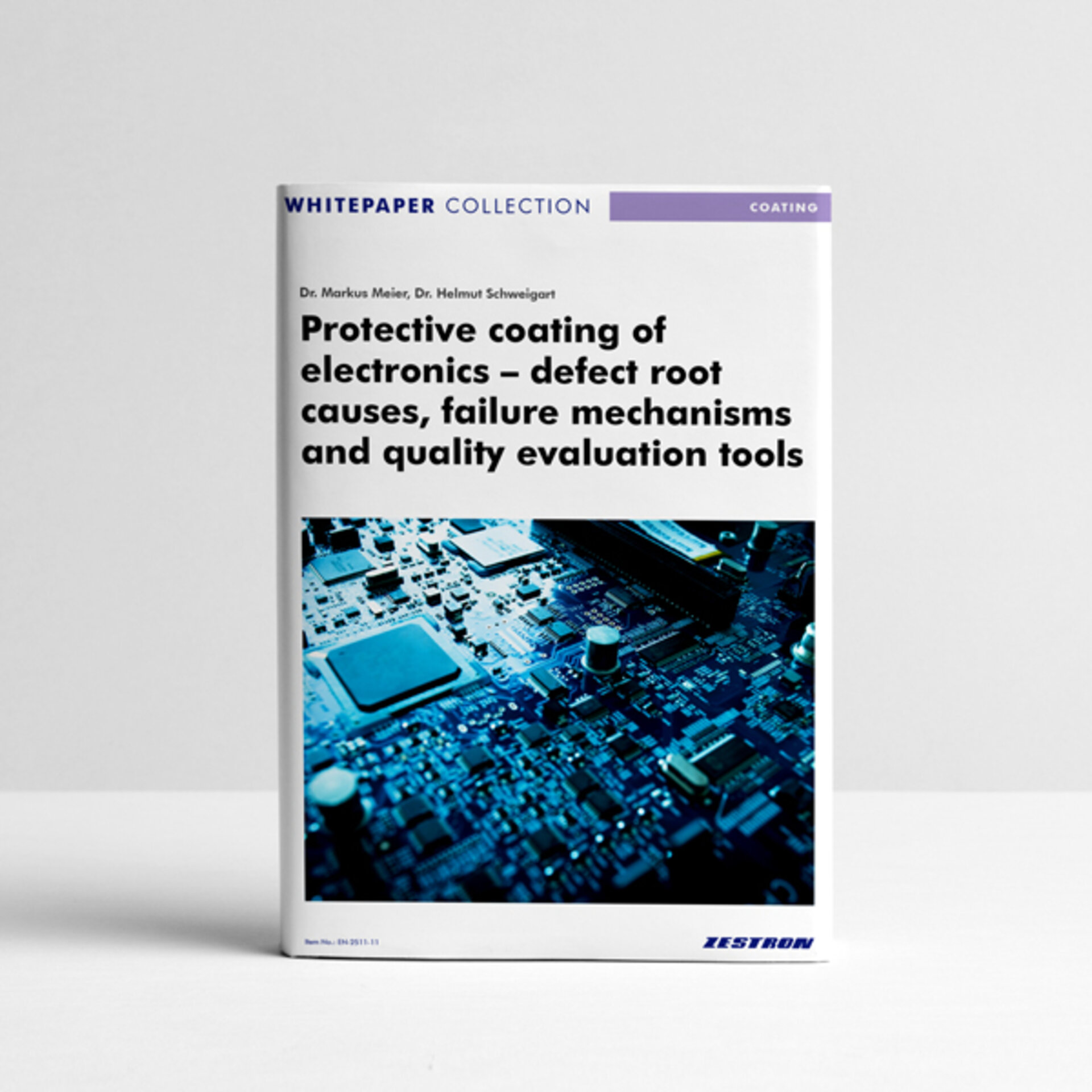

Protective coating of electronics – defect root causes, failure mechanisms and quality evaluation tools

Abstract

Conformal coatings have attained widespread use in applications, which require high reliability electronics especially under harsh climatic conditions such as high humidity load and elevated temperature. The defects mostly observed after stress testing are cracks, delaminations and blisters.

Root causes for the occurrence of these defects mostly are surface properties, drying conditions and geometry of the assembly. Under humidity load, failure mechanisms are triggered by these defects in the protective system. Here, in low and high voltage electronic devices, different humidity induces failure mechanisms are observed.

In opposition to low voltage electronics where leakage currents and electrochemical migration (ECM) are the dominant failure mechanisms, voltage breakdowns and the anodic migration phenomenon (AMP) are mostly found in high voltage devices.

To prevent coating defects and the resulting failures in practice as well as during qualification testing, coating reliability tests can provide a quick assessment of coating quality and its susceptibility to moisture exposure.

This whitepaper offers an overview of the individual test methods used to evaluate coating quality.

Key Topics

-

Influencing factors on coating quality

-

Material and humidity inducted failures

-

Electrochemical Migration (ECM)

-

Anodic Migration Phenomenon (AMP)

-

-

Quality evaluation tools

Originally published in the proceedings of the Electronics in Harsh Environments Conference, Amsterdam, Netherlands, 23-25, May 2023.

Category: Protective Coating | Request: Bookmark this

Dr. Markus Meier

Group Leader Reliability & Surfaces

After his study of chemistry at the Technical University Munich, Markus Meier worked among others on the ageing of cement and earned a PhD on the topic crystallization of cement-hydrate-phases under microgravity conditions. He is experienced in the areas interfacial chemistry and surface analytics. He is part of the Reliability & Surfaces Team in which he is responsible for the coordination of research projects as well as the organization of technology coachings.

Dr. Helmut Schweigart

Head of Reliability & Surfaces

Dr. Helmut Schweigart obtained his doctorate for research into the reliability of electronic sub-assemblies, and he has been employed at ZESTRON Europe since the early days of the company. He is now Head of Reliability & Surfaces Team. He is also a member of the Board of Management at GfKORR (Gesellschaft für Korrosionsschutz - a company specialising in corrosion inhibitors) as well as an active member of GUS (Gesellschaft für Umweltsimulation - an environmental simulation company) and of the IPC. He has already published numerous technical articles.