Failure Assistance and Risk Assessment for PCBAs (SMT)

We support you in the rapid identification of failure causes, provide targeted failure assistance measures, and collaborate with you to develop sustainable risk assessment for PCBA and strategies for long-term failure prevention.“

Failure Assistance and Risk AssessmentElectrical Failures or Qualification Issues with Assembled PCBAs?

With experience from over 800 incidents across automotive, industrial, and other sectors, we deliver traceable corrective actions within a few weeks.

We identify root causes, ensure effective remediation, and develop strategies for long-term risk assessment, always with the highest level of information security and confidentiality in accordance with ISO/IEC 27001 and TISAX.

Failure assistance for pCBAElectrical Damage or Qualification Failures in PCBAs?

Failure assistance for pCBAElectrical Damage or Qualification Failures in PCBAs?

Actual failure causes in PCBAs are identified quickly and transparently, whether from field returns or failed qualifications under automotive standards (e.g., C-samples). This yields specific, actionable recommendations for immediate and lasting remediation.

The underlying root cause often lies not in-house but in changes within the supply chain. As a neutral expert and technical intermediary, support is frequently provided in facilitating dialogue with suppliers.

Rapid and confidential processing can begin immediately.

Operations strictly follow ISO/IEC 27001 and TISAX.

from practiceReliable Support When Incidents Occur

We provide end-to-end support for PCBA incidents, from failure analysis and root cause verification to durable corrective actions.

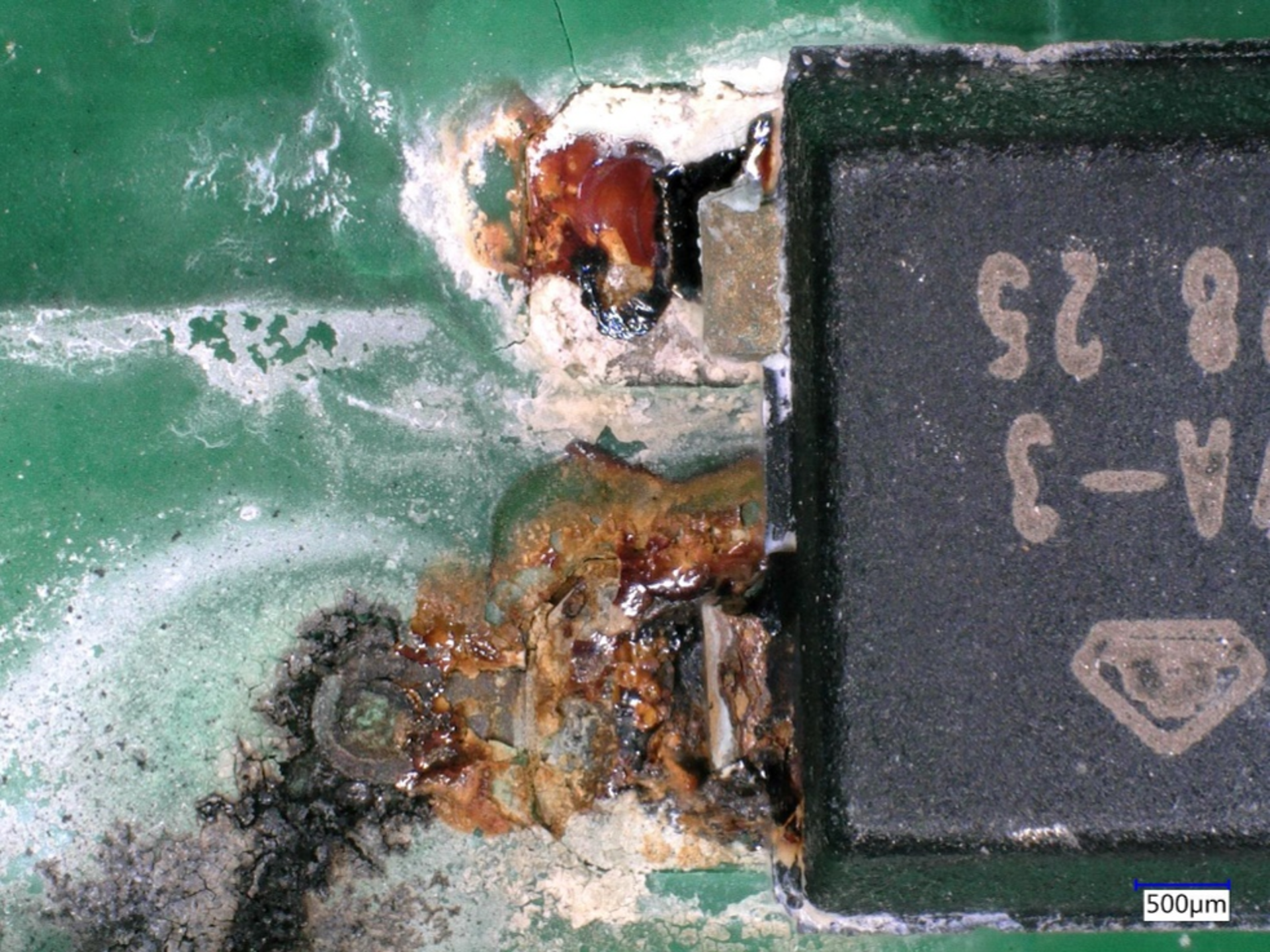

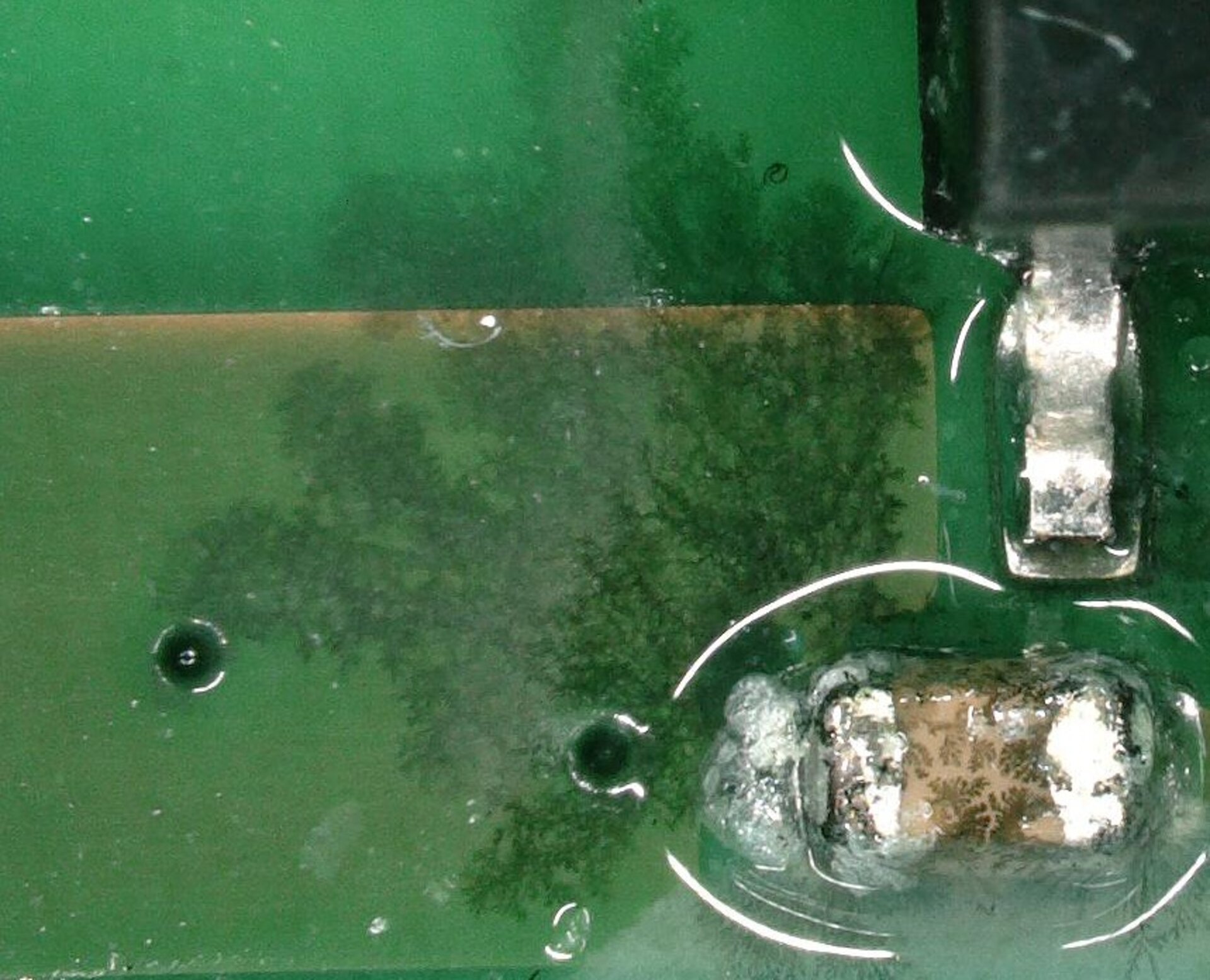

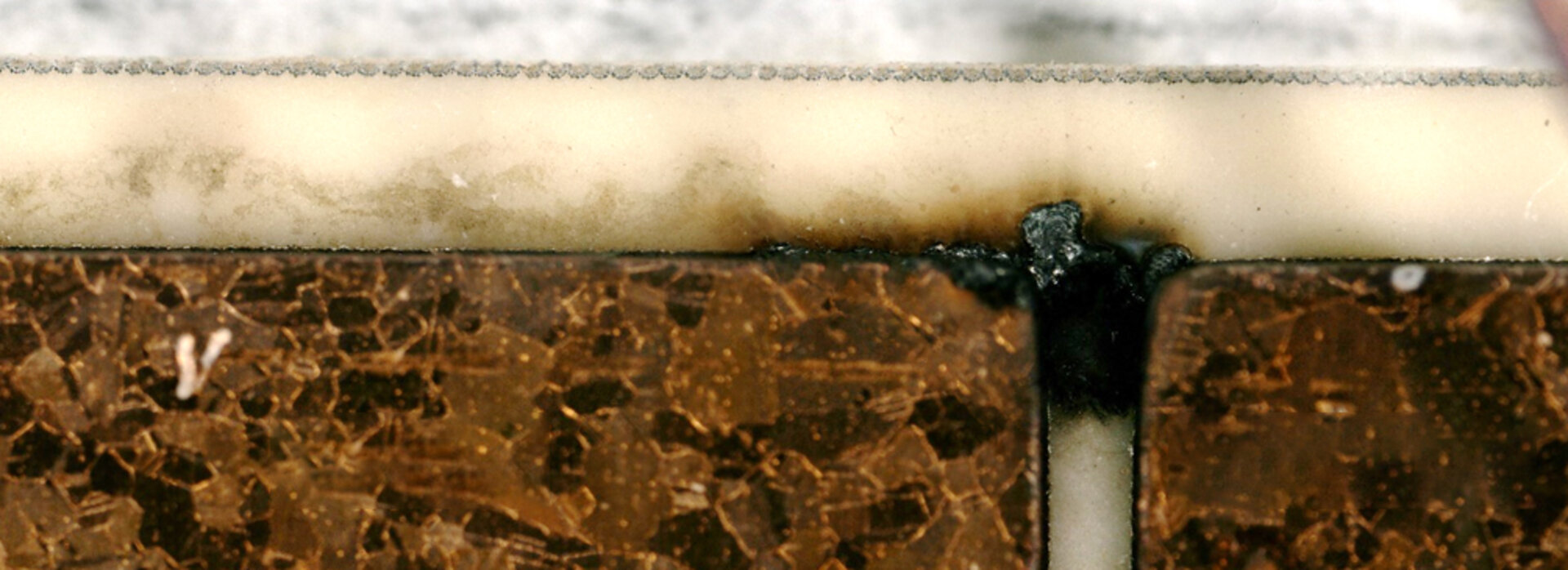

Corrosion and (Green) Discoloration on Electronic Assemblies

Dendrites, Creepage Distances, and Deposits on Electronic Assemblies – All Consequences of Electrochemical Migration?

risk assessment for PCBAEarly Prevention of Particle-related Failures

risk assessment for PCBAEarly Prevention of Particle-related Failures

Critical particles on PCBAs can lead to leakage currents, insulation faults, qualification issues, or field failures. To prevent these risks from appearing in series production, assemblies are systematically assessed for particulate contamination at the early development stage (A-samples).

Process analyses draw on extensive practical experience and established standards such as VDA 19.2, IPC-TR-1771, and IEC 60664. This approach identifies critical points, explains specific failure mechanisms, and provides defensible data for cleanliness specifications and drawing notes.

The outcome is a reliable basis for stable manufacturing SOPs, robust product qualification (e.g., PPAP), and higher delivery reliability through early prevention.

Fast and confidential handling can begin immediately. Operations follow ISO/IEC 27001 and TISAX.

From practice Confidence Through Sound Risk Assessment

Experience from numerous projects shows what really matters when it comes to evaluating technical cleanliness, contamination levels, and process risks.

Your Challenge: Defining the Right Pollution Degree

Ensuring Technical Cleanliness in the Production Process

VDA 19: Technical Cleanliness – The Key to Preventing Particle-Induced Failures