Failure Assistance & Risk Evaluation

Holistic solutions from root cause analysis through implementation, for higher reliability, lower follow-on costs, and secured delivery capability.

failure analysis & risk assessmentExpert Solutions for Failure Analysis and Sustainable Quality Assurance

From root cause analysis and 8D reports to technical cleanliness and process optimization – we help you identify weaknesses at an early stage and implement tailored corrective actions.

Our specialized solutions ensure the quality of your products while reducing legal and financial risks. At the same time, we support compliance with relevant standards and provide long-term reliability for your electronics manufacturing.

assembled pcbs Enhancing Process Reliability in SMT Manufacturing

Even the smallest errors in SMT manufacturing can lead to failures, malfunctions, and quality issues. We help you identify potential sources of error at an early stage, perform targeted analyses, and implement effective measures to increase your production reliability and prevent failures.

power electronics Identify Risks Early Secure Your Power Modules

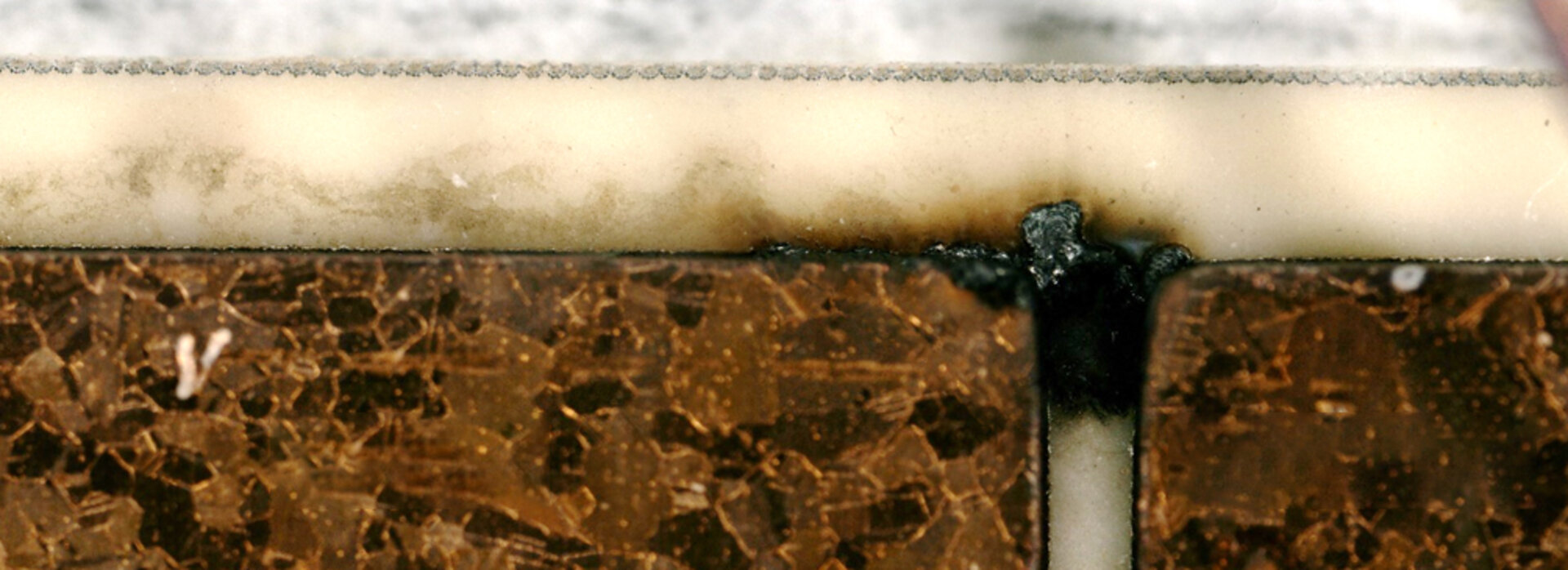

Power modules are exposed to high electrical and thermal stress in many applications. Even minor material weaknesses can cause failures, such as ECM, AMP, or partial discharges. We support you in identifying risks at an early stage, analyzing root causes, and effectively protecting your modules.

failure analysis & risk assessmentOur Contribution to Your Success

We support you in precisely identifying weaknesses, eliminating risks at an early stage, and systematically improving your processes – practical, solution-oriented, and tailored to your specific requirements.

We investigate failure mechanisms (cause) and identify the underlying root cause to enable sustainable corrective actions. Our targeted support in change management ensures long-term solutions for:

- Validation failures in the PPAP process (DV, PV), especially after climate stress tests according to IEC 60068-2, VW 80000, BMW and Mercedes factory standards

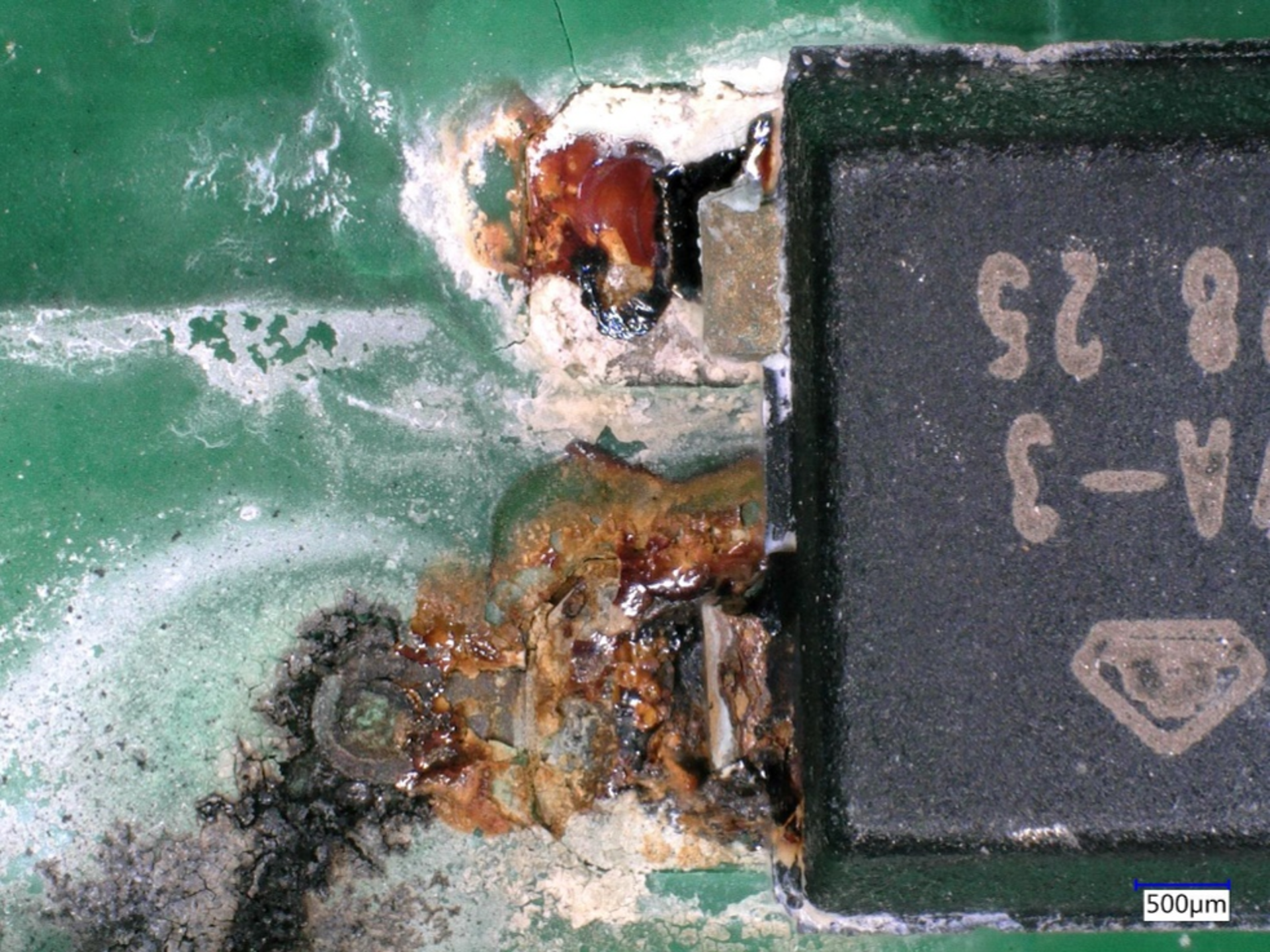

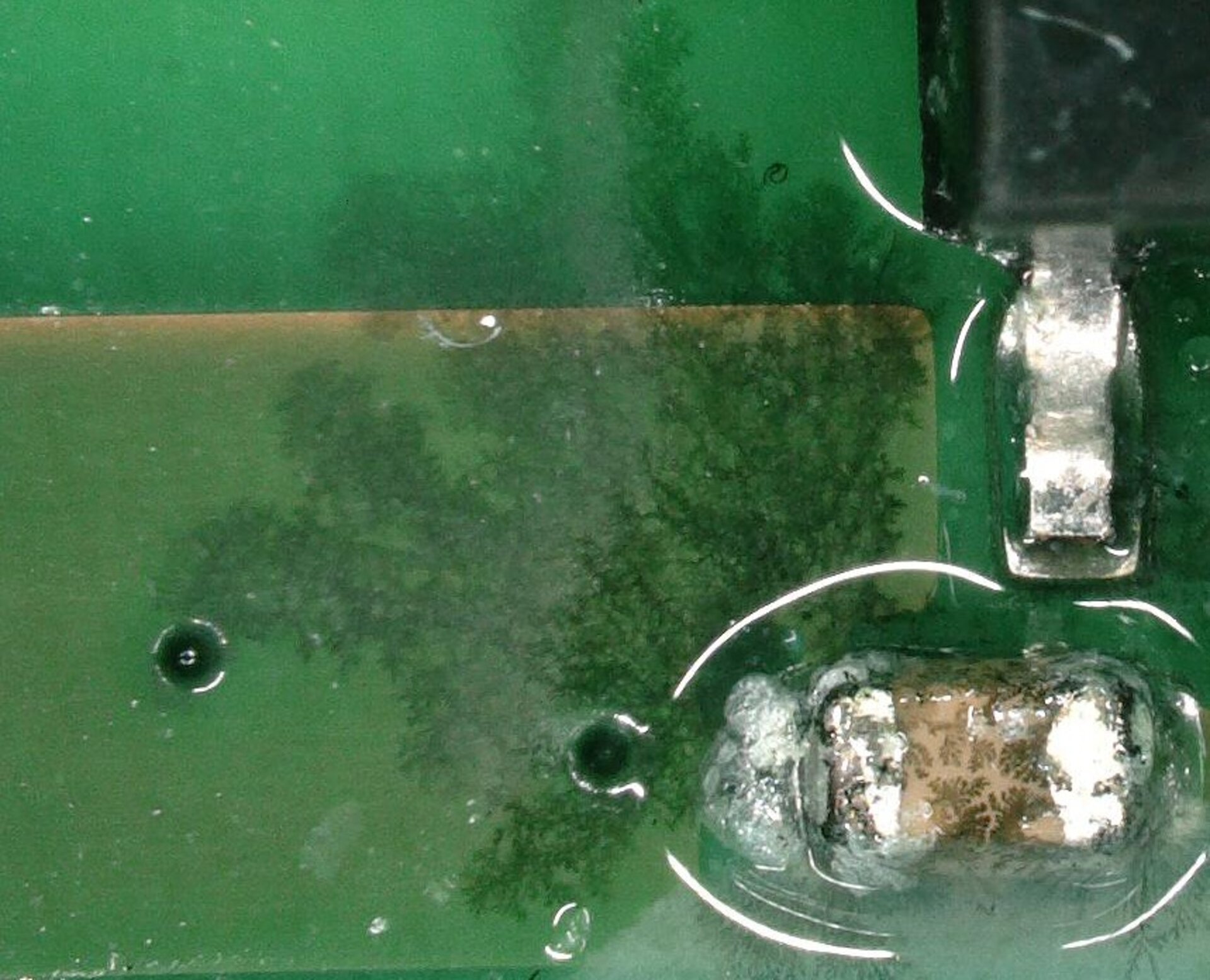

- Dendrite formation (ECM, AMP, partial discharge, creepage corrosion, whiskers)

- Discoloration (corrosion, oxidation, contamination, polymer degradation)

We provide extensive support in preparing 8D reports in order to minimize legal and financial risks while securing supply capability. Our expertise specifically assists with:

- Out-of-court settlements and arbitration decisions

- Claim defense and contract compliance

- Prevention of indirect financial losses (e.g., bank ratings, financial reserves)

- Securing supply capability

We support you in implementing measures to ensure Technical Cleanliness (TecSa) and insulation coordination:

- Implementation support for VDA 19, ZVEI guidelines and IEC TR 61191-7

- Room planning, equipment concepts, audits, risk assessments and training

- TecSa management from strategy and concept development to operational implementation

- Development of a robust Component Cleanliness Code for drawings and specifications to ensure compliance with the agreed level of contamination according to IEC 60664-1 and IPC 2221

We help you to identify weak points in process development at an early stage and to minimize risks effectively to ensure the quality of your products:

- Analysis of product and prototype weaknesses using rapid quality testing methods

- Support with A/B samples

- Advice on and optimization of coating, potting, molding and embedding processes

- Support with sintering processes

practical insightsSolutions for Your Challenge

Our case studies and application examples demonstrate how we precisely analyze failure causes, implement practical solutions and sustainably optimize production processes to successfully overcome technical challenges.

Your Challenge: Defining the Righte Pollution Degree

Corrosion and (Green) Discoloration on Electronic Assemblies

Dendrites, Creepage Distances, and Deposits on Electronic Assemblies – All Consequences of Electrochemical Migration?

VDA 19: Technical Cleanliness – The Key to Preventing Particle-Induced Failures