InsightsResidues on Electronic Assemblies? FTIR Microscopy Reveals What’s Really Behind Them

Whether it’s stains, deposits, or discoloration – with FTIR microscopy, we precisely analyze even the smallest residues and help you identify and resolve the root cause.

FTIR microscopy and SpectroscopyDetecting Residues Is Not Enough – Understanding Them Is Key

Residues on the surface of electronic assemblies are common in practice – but their exact composition often remains unclear. Especially in the case of localized discoloration, stains, or deposits, a visual inspection alone is not sufficient to reliably determine the cause.

In such cases, we rely on Fourier-transform infrared spectroscopy (FTIR). As a powerful analytical technique, it enables the precise characterization of materials on surfaces and directly at the affected site. This provides crucial insights for evaluating and classifying residues and deriving appropriate corrective actions.

method selectionWhen Is FTIR Spectroscopy – and When Is FTIR Microscopy – the Right Choice?

-

Analysis of powders or liquids

FTIR spectroscopy is a proven method for the chemical analysis of organic substances. -

Analysis of residues or stains on components

FTIR microscopy is the method of choice here. It enables non-destructive and spatially resolved measurements on the surface of electronic assemblies

FTIR-Microscpoy

-

Technique for qualitative and (semi-)quantitative analysis of organic residues on surfaces

-

Analysis of areas ≥ 5 x 5 μm

-

Identification of the chemical structure of contaminants, residues, films, particles, etc.

From practiceTargeted Residue Analysis – Clear Assessments

Residues on assembly surfaces such as flux and its by-products, films, oils, fibers, or particulate contamination can be identified using FTIR microscopy, allowing their possible causes to be narrowed down. Whether in the context of a complaint, serial deviation, or pre-series assurance – you receive precise results for well-founded root cause analysis.

ProblemDiscoloration on a populated PCB

A customer asked our team of experts for support with the following issue:

01 | Inital Situation

Thin, widespread residue on a populated PCB.

02 | Customer Request

The aim was to clearly identify the residues and evaluate their potential impact on the assembly’s functionality.

03 | Our Approach

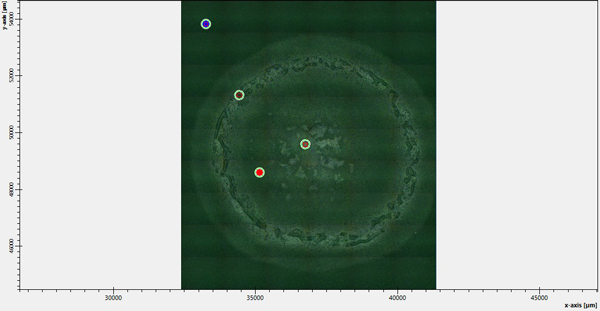

A purely visual assessment was insufficient, so spatially resolved FTIR microscopy was used.

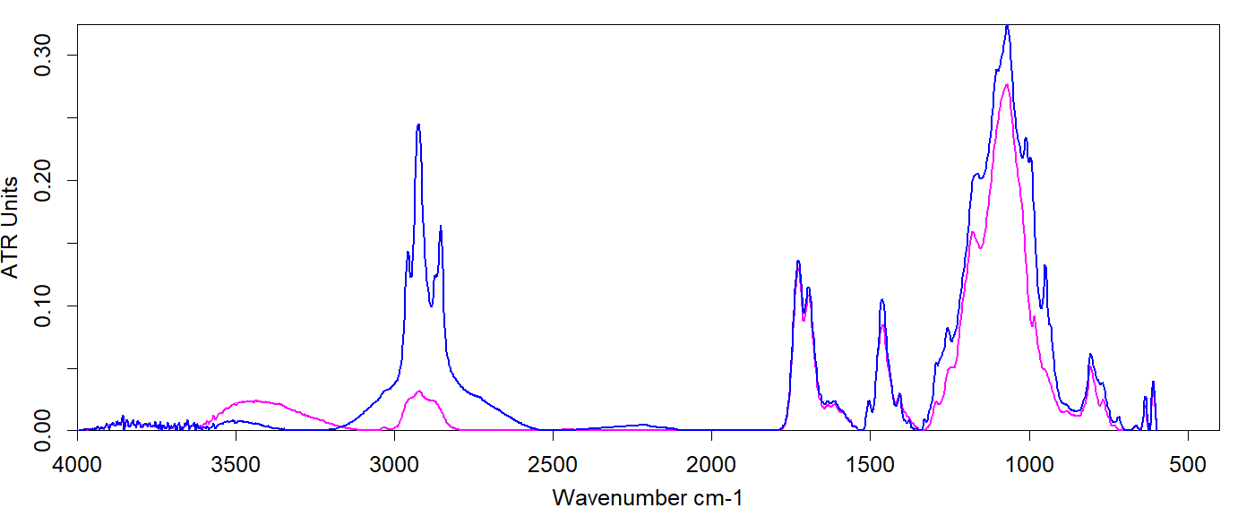

After evaluating the obtained FTIR spectrum, including its specific bands indicating functional groups, and comparing it with reference data from our extensive databases, the chemical nature of the compound was identified.

(Image: Magnification of the residue and spatially resolved FTIR microscopy analysis)

(Image: IR spectra of the residue and a reference site)

The analysis provided concrete insights into the residue’s chemical composition, forming the basis for further root cause clarification and the development of specific corrective actions in collaboration with our R&S expert team.

undefined residues or discolarations?How Can ZESTRON Support You?

Analytics to the Point

FTIR microscopy enables spatially resolved characterization of organic residues on surfaces – for targeted identification of substances directly at the affected site.

Extensive Reference Databases

We draw on a wide range of databases and continually expand them based on our customer projects to enable fast and reliable residue assessment.

Actionable Results – Concrete Solutions

We provide you with a fast, comprehensible evaluation of your issue. On request, we also support you in interpreting the results and developing specific corrective actions.

residues or discolerations in your process?We Support You in Clarifying the Root Cause

When residues or discolorations raise questions, a reliable analytical basis is key. FTIR microscopy can help identify unknown substances – directly at the affected site, without complex sample preparation.

We support you with the right analytics – for residues, process safety, or complaints.

whitepaper-collectionResidues on PCBAs - Causes and Remidial Measures

White spots, streaks, or solder balls – visible residues can impair the function of electronic assemblies. This whitepaper highlights common causes and offers practical recommendations for optimization.