Low-Standoff-Cleaning - Avoid contamination and malfunctions

We show you how to overcome the Challenge.

time for a fact checkCleaning Under Components

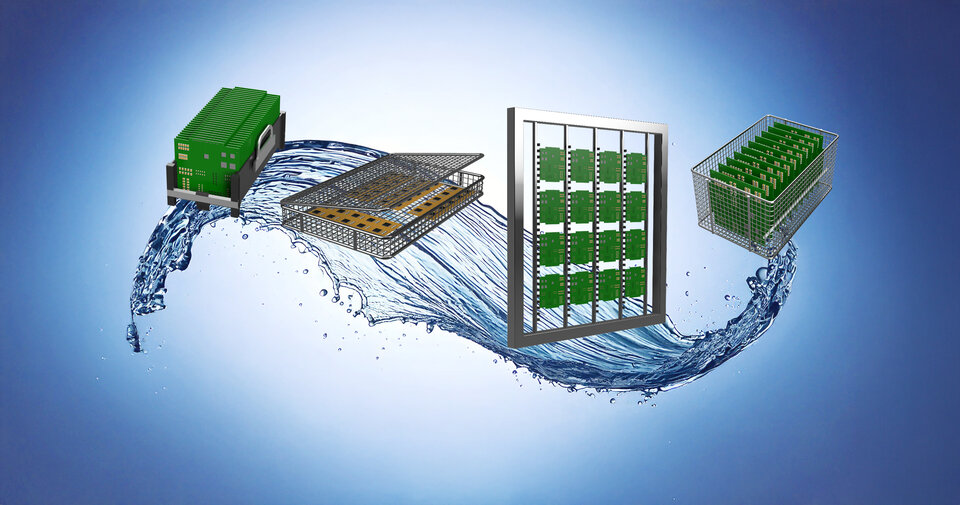

On the Test Bench: Which Cleaning Method is Most Suitable?

The cleaning of low-standoffs - i.e. in narrow gaps between components and PCB - is considered a special challenge in component cleaning. This is because flux and other production residues can lead to malfunctions and must therefore be completely removed, especially under the components. This is no easy task, as the distances between the PCB and the components are usually only a few micrometres high.

But how can low-standard-offs be cleaned in the best possible way without leaving residues? In the fact check you will not only get an answer to this question, but you will also find out what role the components and their size play. Scientifically verified!

Watch the Fact Check in the Video ▼

fact check to readLow-Standoff Cleaning

On the Test Bench: Various Components and Appropriate Cleaning Methods

When Does a Gap Become a Low Standoff?

There is no precise definition of when a gap height is considered low-standoff and thus particularly low. However, our many years of experience in the installation and support of cleaning processes allow us to make an assessment. In fact, it depends on the components themselves. Depending on which component is considered, there are different gaps and thus also different gap heights that can be considered low-standoffs.

For SMT components such as QFNs, LGAs, MLFs or DFNs, distances in the range of 50 and 75µm between the component and the PCB are already referred to as low-standoffs.

The situation is different in the production of advanced packaging components such as flip chips or system-in-packages such as PoPs, TSVs or 3D ICs with microbumps and copper pillars. Here, the gaps are only between 10 - 40µm.

Can Cleaning Achieve More Than Flux Removal Alone?

Even when cleaning under components, the primary goal is to avoid malfunctions and failures of the assembly. After all, leakage currents or electrochemical migration no longer stand a chance.

There are also other advantages: for example, there is better adhesion between the PCB surface and the component's encapsulation material. In the production of advanced packaging components, cleaning also achieves the optimum surface energy for the subsequent underfill.

Cleaning, especially under low-standoff conditions, therefore, contributes significantly to the reliability of the entire system.

What Challenges Does Cleaning Pose?

Penetrating the narrow gaps and spaces with the cleaner and dissolving the flux residues as well as rinsing the gap again without leaving any residue - these are the challenges with low-standoffs. Here, the ratio of component size to standoff height is particularly important.

With the appropriate cleaning process, the challenge is overcome.

But Which Method Is Best for Cleaning Underneath Components?

ZESTRON has tested it scientifically and conducted cleaning trials with standoffs between 10 -40µm. We have concentrated on the cleaning of PCBAs with low-standoff components.

Ask now and you will learn in detail and in an understandable way:

-

What the specific challenges are in cleaning underneath components and why.

-

What role the size ratio of component to standoff height plays

-

And which cleaning process is best suited for low standoffs