Reliably Test Opaque-Encapsulated Power Modules

Non-destructively identify root causes and effective corrective actions using electrical impedance spectroscopy (EIS).

Electrical impedance spectroscopy (EIS) Reliable Detection and Evaluation of Failures in Encapsulated Power Electronics

When power modules are fully encapsulated or inaccessible due to molding processes, conventional testing methods reach their limits.

Imaging methods such as ultrasound microscopy show structural defects, but do not answer whether the insulation capability or the electrical behavior is impaired.

Electrical impedance spectroscopy detects frequency-dependent electrical changes non-destructively that indicate blisters, cracks, delamination, or the effects of moisture, thus enabling a functional assessment of insulation performance.

This allows relevant weak points to be identified at an early stage and suitable measures to be derived before failures or consequential damage occur.

Electrical impedance spectroscopyA Method for Reliable Condition Assessment

You receive a quantitative statement on the electrical condition of encapsulated power modules. The results supplement imaging methods with a functional assessment of the insulation effect and show whether findings such as bubbles, cracks, delamination or moisture actually affect the function. The assessment is precise and non-destructive; the module remains operational.

We collect the measurement data using electrical impedance spectroscopy (EIS).

Faster to the cause, sooner to the solution

Analyses that would otherwise take days of intensive troubleshooting are often completed within a few hours. This reduces downtimes, speeds up process validation and avoids replacements on suspicion.

The procedure is suitable for fault analysis in the event of field failures as well as for preventive evaluation in product and process development.

Analysis method Application and Validation

EIS can be applied directly to the installed module and is compatible with the requirements of IEC 61189-2-720.

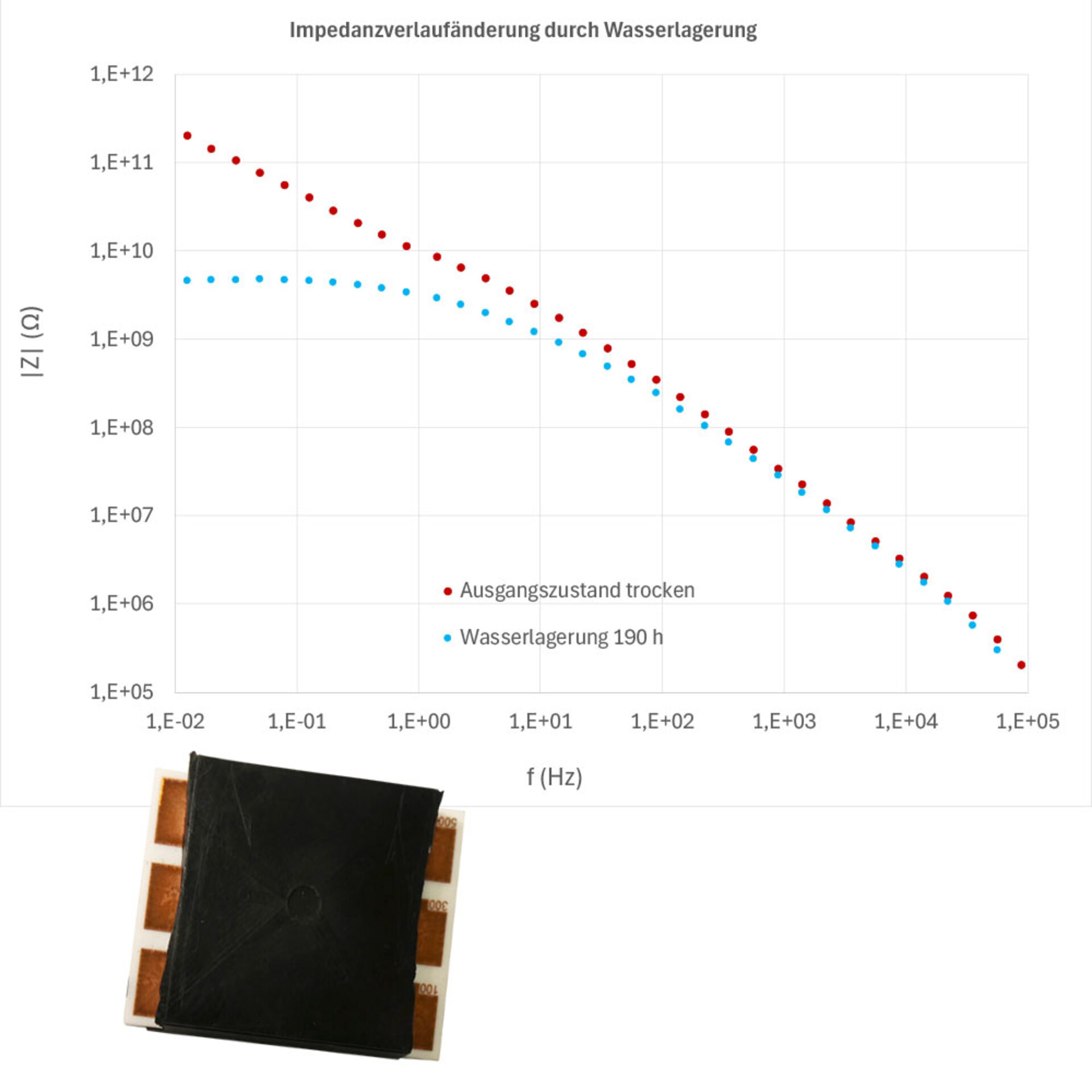

By combining it with accelerated stress tests, changes caused by moisture or temperature stress can be detected.

Comparative measurements, e.g. by means of electrical impedance spectroscopy before and after such tests, allow conclusions to be drawn about the moisture resistance and long-term reliability of a module.

Typical applications:

-

Evaluation of molding and potting processes

-

Identification of delaminations, cracks and bubbles

-

Investigation of the effects of moisture exposure

-

Support for process validation and field failures

Key BenefitsYour Benefits at a Glance

Anyone who manufactures power electronics knows that the longer troubleshooting takes, the higher the costs, downtime and uncertainty in production. This is precisely where we come in and create a measurable time advantage, supported by electrical impedance spectroscopy (EIS).

- Technical

Quantitative evaluation of the electrical condition of encapsulated power modules

Supplement to imaging methods for a complete diagnostic image

Test setup based on IEC 61189-2-720 (capacitive defect detection) - Economical

Faster root cause analysis and fewer downtimes

Early detection of critical conditions in qualification and field

Reduced replacement and testing costs - Practical

Use for monitoring in the production process

Support for material validation and process optimization

Well-founded interpretation by experienced experts

Talk to us

Competent supportFrom Measurement to Process Optimization

The measurement results of electrical impedance spectroscopy (EIS) are interpreted in a practical manner and are directly incorporated into the improvement of your processes. Together with your team, causes are analyzed, measures are derived and solutions are implemented that have a long-term effect. The analysis results in a measurable improvement in the quality and reliability of your power electronics.

whitepaper collectionNon-destructive method for quality assessment of insulation materials in signal & power electronics

Reliability of power modules is key in automotive and energy technology. Epoxy mold compounds protect against temperature changes, moisture and harmful gases. Electrical impedance spectroscopy with HAST evaluates the quality and uncovers weak points within hours to a few days.

assistance moduleDamage analysis for corrosion and leakage currents

Are your power modules at risk due to corrosion, leakage currents or dendrites?

Our specialized remedial module helps you to identify weak points at an early stage and develop sustainable strategies for stable performance and reliable power electronics.