Low-Standoff Cleaning

Christoph Karl, Kristyna Zakova

» free «

Brief Insight

Decreasing standoff heights and larger chip packages pose new challenges for assembly cleaning. This white paper examines how component geometry and size affect cleanability and which technologies can reliably clean even in narrow gaps.

Delivery form: PDF

Article number: EN-2504-05

White paper

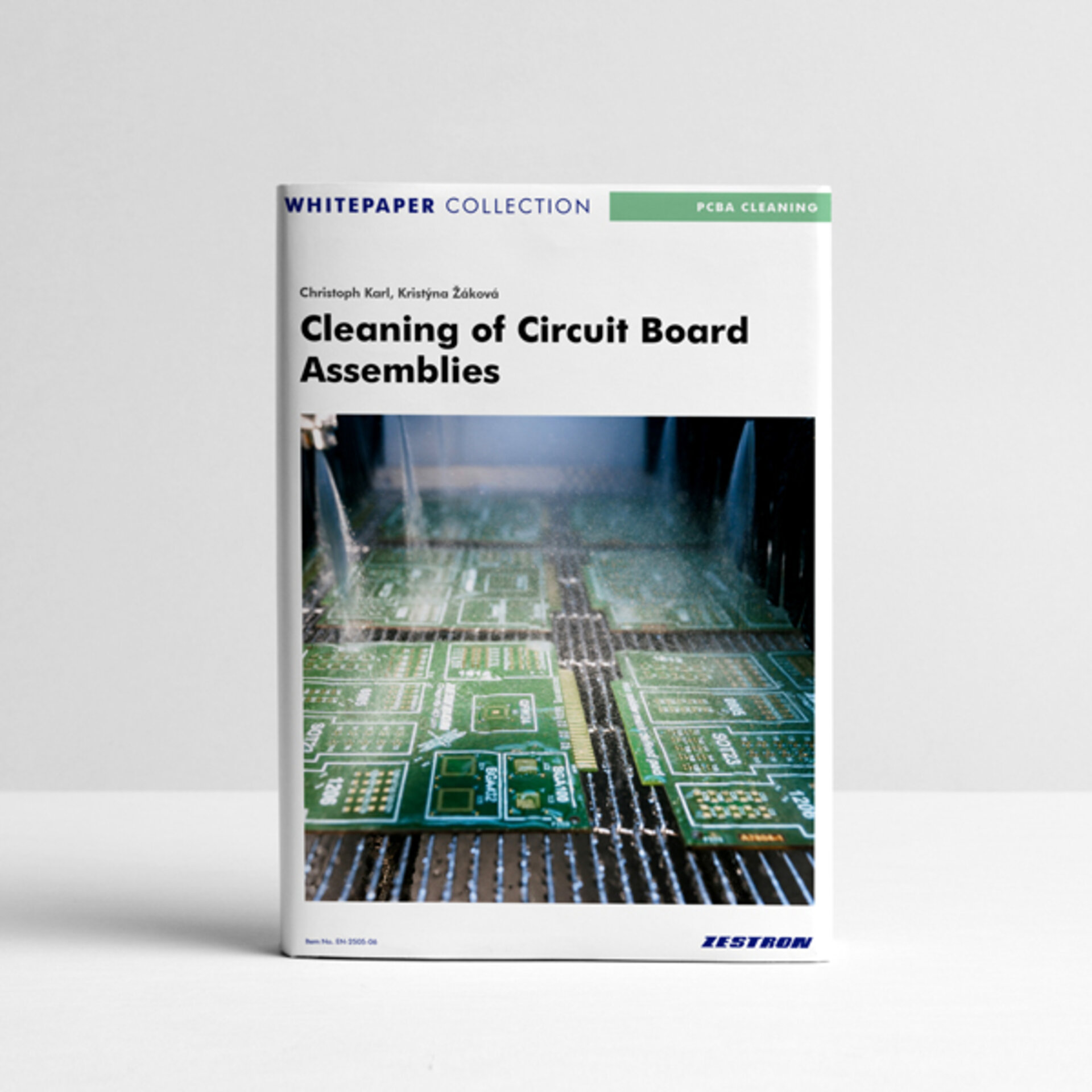

Low-Standoff Cleaning

Abstract

Standoffs in electronics refer to the defined gap between the printed circuit board (PCB) and the underside of surface-mounted components, and they are present in large numbers on any SMT (Surface Mount Technology) assembly. With ongoing miniaturization, many components and their solder joints are continuously decreasing in size, resulting in smaller standoff heights relative to the PCB. In parallel, specialized chip packages with high computational performance, such as those used in servers for AI applications, are increasing in footprint.

Cleaning technologies must keep pace with both trends to ensure reliable contaminant removal within the confined spaces under such components. This whitepaper therefore examines the influence of standoff gap geometry on the cleaning process, beginning with a theoretical analysis followed by practical experimentation. It explores how gap height and component size affect the required cleaning time and investigates whether aqueous cleaning encounters limitations at specific dimensional thresholds. Furthermore, experimental results are used to determine which cleaning technologies are particularly effective for cleaning under lowstandoff components.

Key Topics

-

Theory of Cleaning and Flow below Components

-

Fluid Mechanics Hyothesis

-

Experimental Design

-

Results & Discussion

Category: PCBA Cleaning | Request: Bookmark this

Christoph Karl

Project Engineer Applied Research

Christoph Karl studied Mechanical Engineering with a specialization in Materials Engineering, earning a Dipl.Ing. degree. He then worked at the University of Birmingham and in the automotive supply industry.

At Zestron, he is active in the Applied Research Group, where he oversees topics and research projects related to metrology, analytics, plant engineering, and Design of Experiment (DoE).

In the Applied Research Group, he collaborates with R&D and application technology to develop new methods for analyzing cleaning under components and presents results in a highly targeted manner.

Kristyna Zakova

Project Engineer Applied Research

Kristyna Zakova studied Mechanical Engineering with a focus on Manufacturing Technology and Quality Management at the University of West Bohemia in Pilsen and worked during her studies in the Material Innovation Lab at an LED manufacturer. Afterward, she was employed in Quality Management at a manufacturer of industrial cleaning systems, where she was also responsible for system tests and FACs.

At Zestron, she works in the Applied Research department, engaging in research projects both internally and in cooperation with external partners. Her focus is on analytics, particularly ion chromatography and technical cleanliness, as well as the exploration of new analytical methods and the requirements for cleaning challenging surfaces. Thanks to her practical experience in the lab and plant engineering, she places great emphasis on the feasibility and real-world applicability of research results.